FEATURE

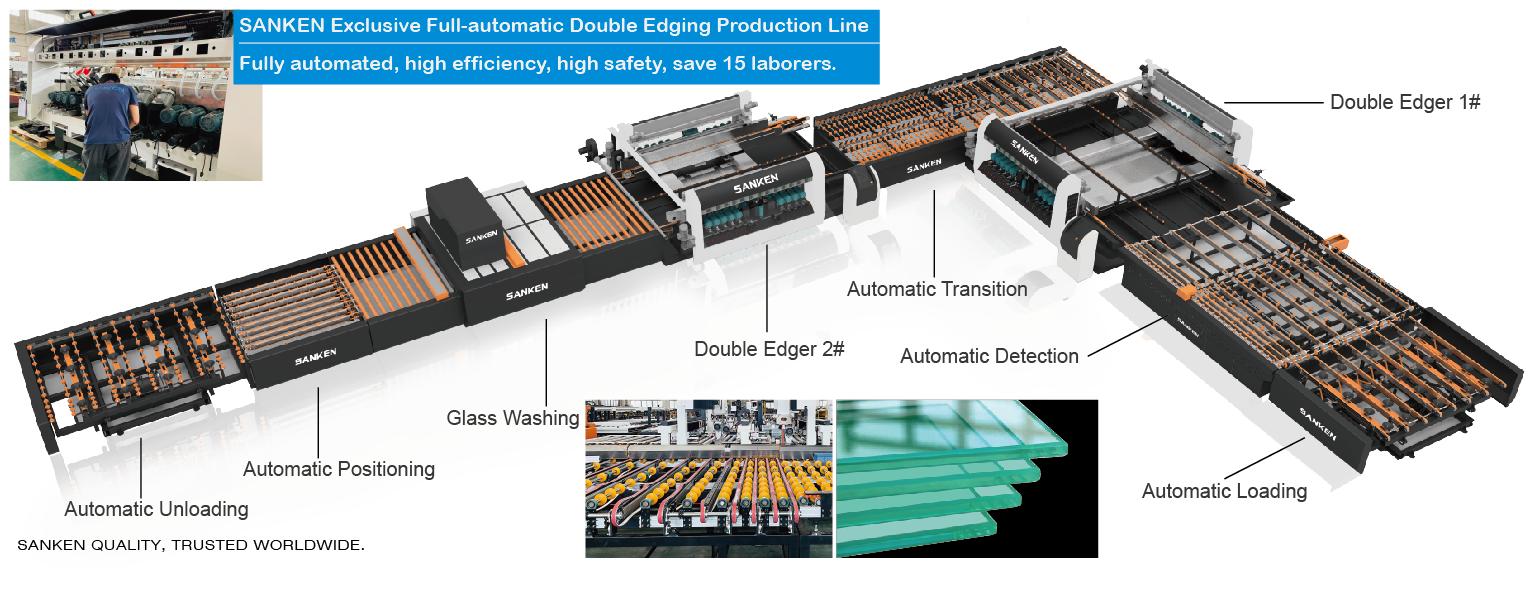

SANKEN double edger equipments, positioned at the highest end of the glass deep processing industry, we made this double edger equipments, with the most advanced technology and the best materials. The SANKEN double edger equipments, has the advantages of straight edge high-efficiency processing, good glass polishing effect, high equipment stability, extremely low failure rate, full automation, and convenient maintenance.

The main components of the double edger equipments, are composed of glass loading section, glass grinding section and glass unloading section. The main body of double edger equipments,, made of stainless steel or other specially treated steel, is durable and corrosion resistant. The double edger equipments, is all driven by servo motors, and the operation can be controlled by PLC touch screen. SANKEN glass has a frequency conversion speed control system on both sides, which can automatically detect the size and thickness of glass of different sizes and thicknesses, and also has an automatic compensation function to ensure the best grinding and polishing effect. Equipment maintenance is very simple, such as automatic alarm prompting replacement of grinding wheel wear, to ensure that the moving part of the glass is clean and tidy, and there is no glass slag, so as to ensure that the glass will not be damaged by gaps. It is very helpful to the processing effect. With the washing machine, drilling machine, etc., a complete automatic glass processing production line can be formed.

SANKEN double edger equipments, positioned at the highest end of the glass deep processing industry, we made this double edger equipments, with the most advanced technology and the best materials. The SANKEN double edger equipments, has the advantages of straight edge high-efficiency processing, good glass polishing effect, high equipment stability, extremely low failure rate, full automation, and convenient maintenance.

The main components of the double edger equipments, are composed of glass loading section, glass grinding section and glass unloading section. The main body of double edger equipments,, made of stainless steel or other specially treated steel, is durable and corrosion resistant. The double edger equipments, is all driven by servo motors, and the operation can be controlled by PLC touch screen. SANKEN glass has a frequency conversion speed control system on both sides, which can automatically detect the size and thickness of glass of different sizes and thicknesses, and also has an automatic compensation function to ensure the best grinding and polishing effect. Equipment maintenance is very simple, such as automatic alarm prompting replacement of grinding wheel wear, to ensure that the moving part of the glass is clean and tidy, and there is no glass slag, so as to ensure that the glass will not be damaged by gaps. It is very helpful to the processing effect. With the washing machine, drilling machine, etc., a complete automatic glass processing production line can be formed.

中文

中文

English

English

español

español

Français

Français

русский язык

русский язык

عربية

عربية