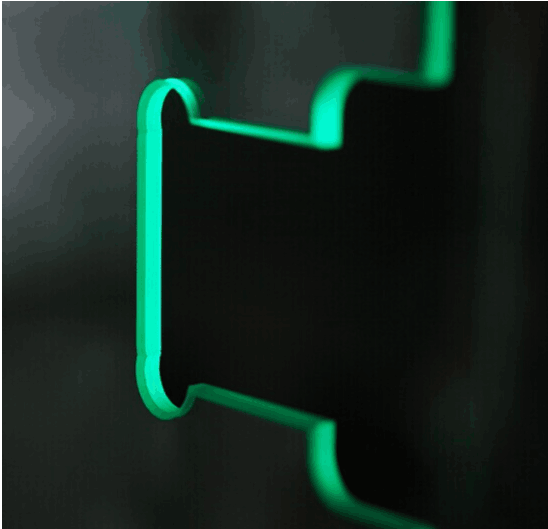

Es ampliamente utilizado en el procesamiento profundo de todo tipo de productos de vidrio regulares o de formas especiales, como paredes exteriores de vidrio, puertas y ventanas de vidrio, cuartos de ducha, mamparas de vidrio, cercas de vidrio, vidrio para automóviles, vidrio para muebles, vidrio para electrodomésticos, arte. vidrio, vidrio decorativo, etc.

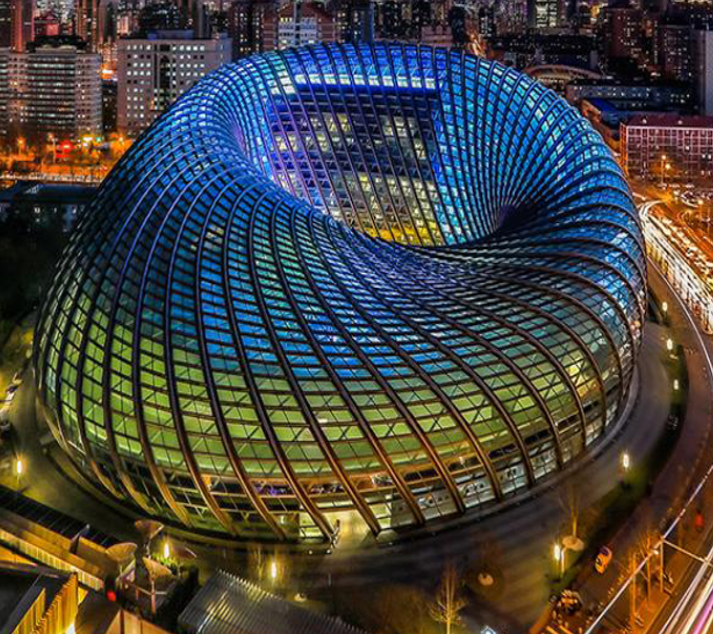

Escena: todos los edificios, tales como: residencias, restaurantes, hoteles, edificios de oficinas, escuelas, hospitales, bancos, estaciones, instalaciones públicas, supermercados, tiendas diversas, etc., así como la industria del mueble, la industria de electrodomésticos, la industria del automóvil, industria del vidrio fotovoltaico, etc.

Es ampliamente utilizado en el procesamiento profundo de todo tipo de productos de vidrio regulares o de formas especiales, como paredes exteriores de vidrio, puertas y ventanas de vidrio, cuartos de ducha, mamparas de vidrio, cercas de vidrio, vidrio para automóviles, vidrio para muebles, vidrio para electrodomésticos, arte. vidrio, vidrio decorativo, etc.

Escena: todos los edificios, tales como: residencias, restaurantes, hoteles, edificios de oficinas, escuelas, hospitales, bancos, estaciones, instalaciones públicas, supermercados, tiendas diversas, etc., así como la industria del mueble, la industria de electrodomésticos, la industria del automóvil, industria del vidrio fotovoltaico, etc.

中文

中文

English

English

español

español

Français

Français

русский язык

русский язык

عربية

عربية