中文

中文

English

English

español

español

Français

Français

русский язык

русский язык

عربية

عربية

玻璃深加工设备

Processing Equipments

Equipos de procesamiento

Équipements de traitement

Оборудование для обработки

معدات المعالجة

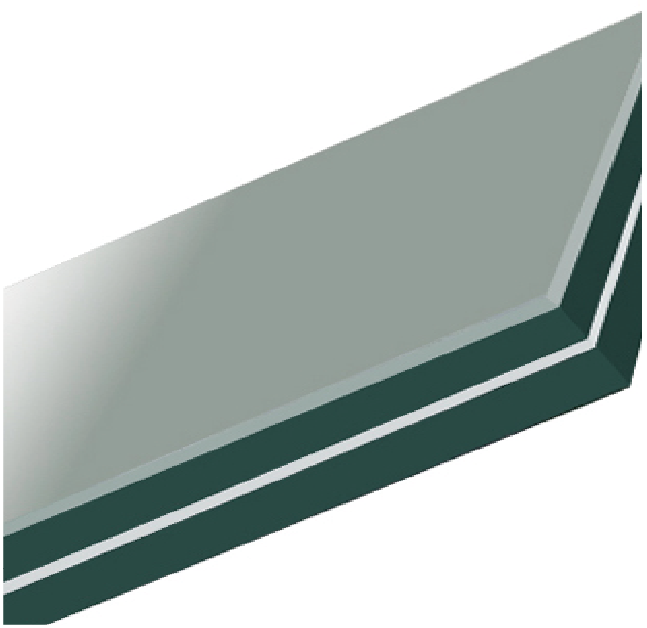

玻璃深加工生产线

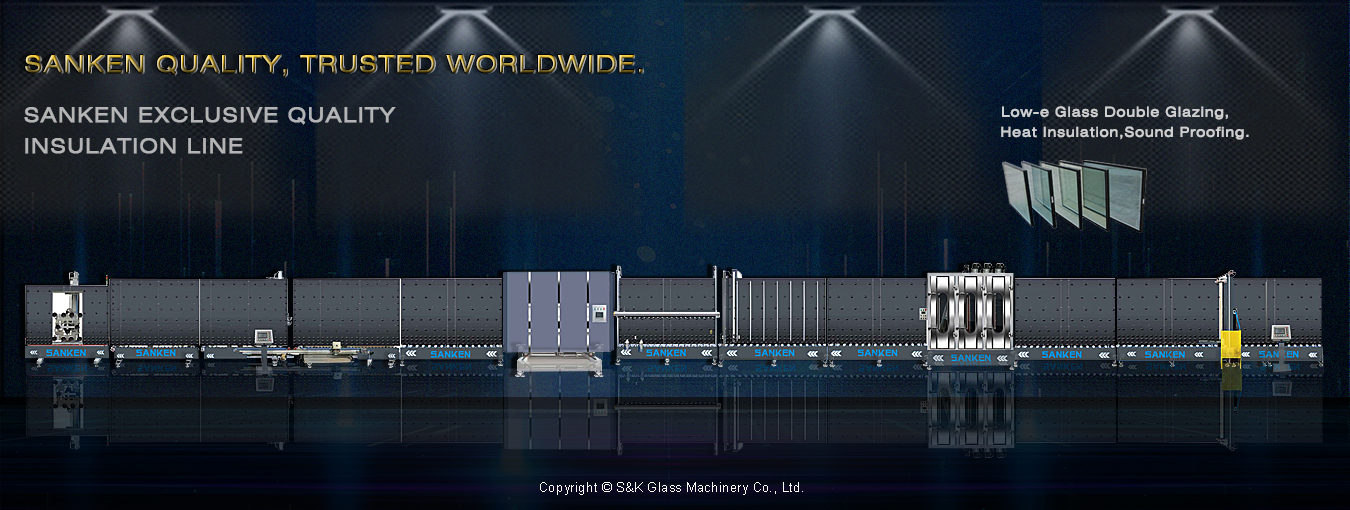

Processing Lines

Líneas de procesamiento

Lignes de traitement

Линии обработки

خطوط المعالجة

浮法玻璃原片生产线

Float Production Line

Línea de producción flotante

Ligne de production de flotteurs

Линия по производству поплавков

خط إنتاج تعويم