CARACTÉRISTIQUE

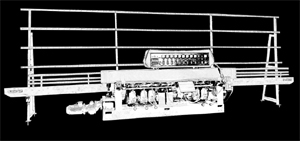

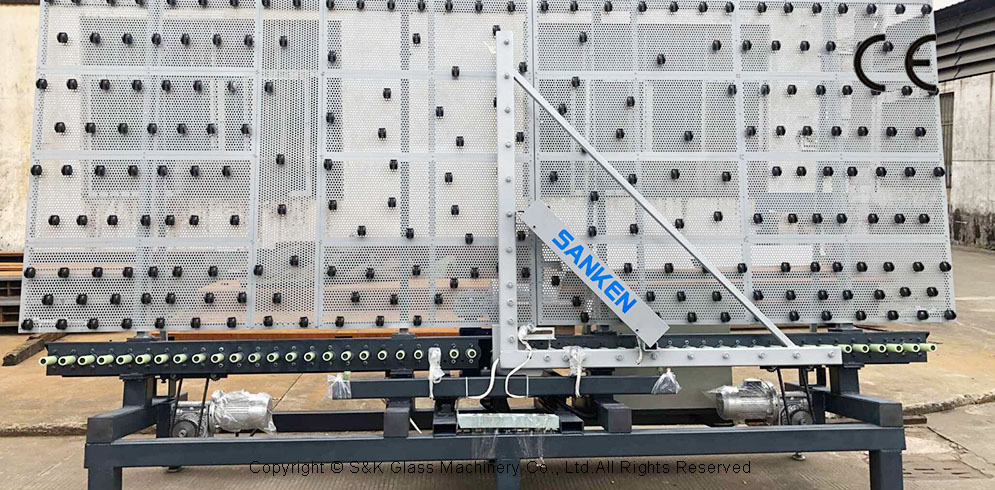

La ligne de production de bordures verticales à plusieurs niveaux SANKEN est positionnée à l'extrémité supérieure de l'industrie du traitement en profondeur du verre, nous avons fabriqué ce type de chaîne de production de bordures verticales à plusieurs niveaux avec la technologie la plus avancée et fabriquée avec les meilleurs matériaux. La ligne de production de bordures à onglets verticales à plusieurs niveaux SANKEN présente les avantages d'un effet de polissage du verre parfait, avec une stabilité élevée, un taux d'échec extrêmement faible et une maintenance très pratique.

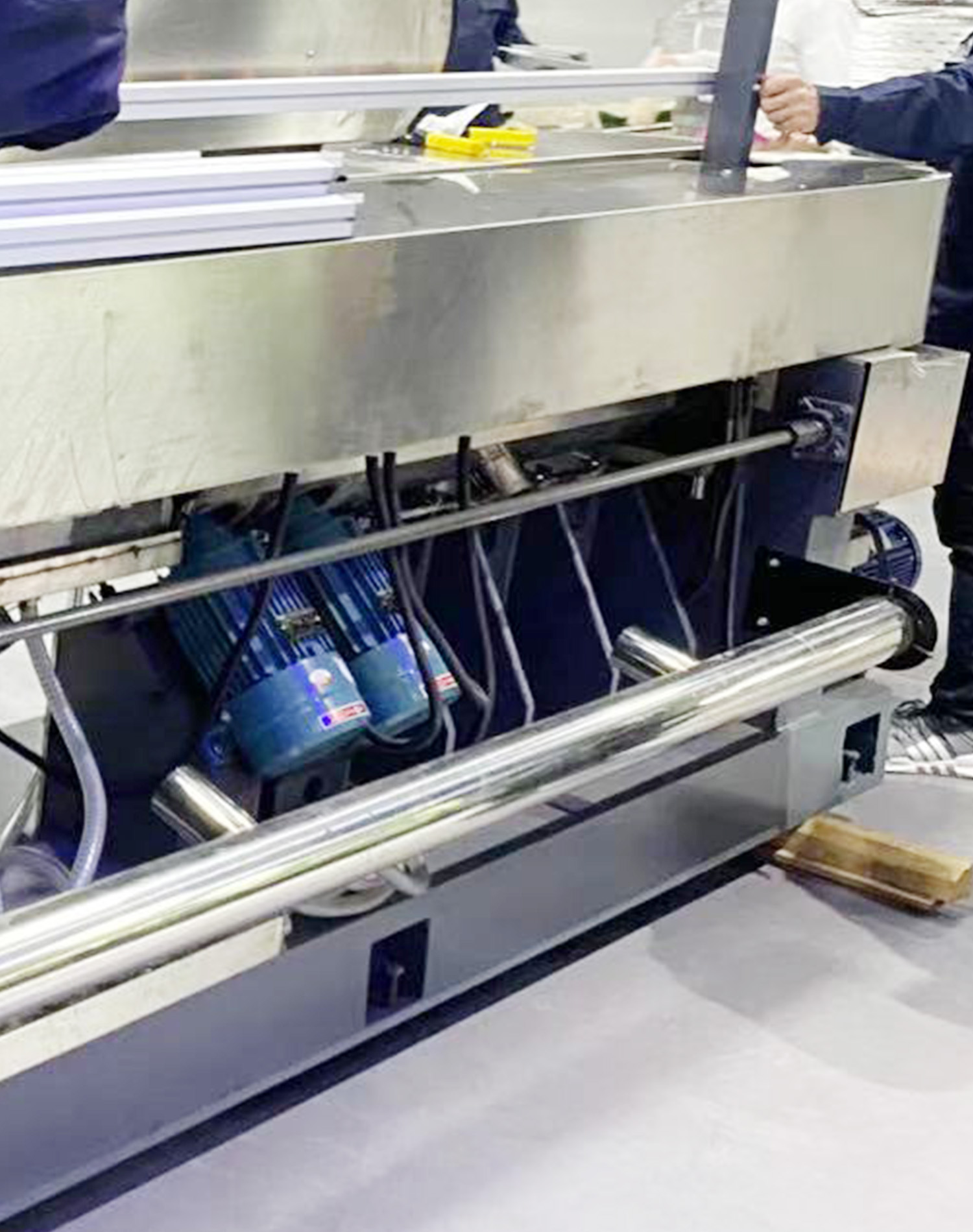

Les parties principales de la ligne de production de bordures verticales à plusieurs niveaux sont combinées avec une section de chargement du verre, une section de meulage du verre et une section de déchargement du verre. La couverture de protection et le cadre de la structure sont installés avec de l'acier inoxydable ou un autre acier de traitement spécial. L'opération peut être contrôlée par écran tactile ou non, ce qui est facile à utiliser. Et la ligne de production de bordures à onglets verticales à plusieurs niveaux de SANKEN, un système de contrôle de la vitesse de fréquence, pour différentes tailles et épaisseurs de verre, a le meilleur effet de meulage et de polissage. Par exemple, le verre peut fournir de l'huile lubrifiante et nettoyer la plaque de pression en verre à l'intérieur de l'équipement pour s'assurer que la partie mobile du verre est propre et bien rangée, et qu'il n'y a pas de scories de verre, afin de garantir que le verre ne sera pas ébréché et endommagé. Il sera très utile pour l'entretien des clients à l'avenir.

La ligne de production de bordures verticales à plusieurs niveaux SANKEN est positionnée à l'extrémité supérieure de l'industrie du traitement en profondeur du verre, nous avons fabriqué ce type de chaîne de production de bordures verticales à plusieurs niveaux avec la technologie la plus avancée et fabriquée avec les meilleurs matériaux. La ligne de production de bordures à onglets verticales à plusieurs niveaux SANKEN présente les avantages d'un effet de polissage du verre parfait, avec une stabilité élevée, un taux d'échec extrêmement faible et une maintenance très pratique.

Les parties principales de la ligne de production de bordures verticales à plusieurs niveaux sont combinées avec une section de chargement du verre, une section de meulage du verre et une section de déchargement du verre. La couverture de protection et le cadre de la structure sont installés avec de l'acier inoxydable ou un autre acier de traitement spécial. L'opération peut être contrôlée par écran tactile ou non, ce qui est facile à utiliser. Et la ligne de production de bordures à onglets verticales à plusieurs niveaux de SANKEN, un système de contrôle de la vitesse de fréquence, pour différentes tailles et épaisseurs de verre, a le meilleur effet de meulage et de polissage. Par exemple, le verre peut fournir de l'huile lubrifiante et nettoyer la plaque de pression en verre à l'intérieur de l'équipement pour s'assurer que la partie mobile du verre est propre et bien rangée, et qu'il n'y a pas de scories de verre, afin de garantir que le verre ne sera pas ébréché et endommagé. Il sera très utile pour l'entretien des clients à l'avenir.

中文

中文

English

English

español

español

Français

Français

русский язык

русский язык

عربية

عربية